| Pipeline type homogeneous emulsion pump (single-stage) |

|

|

Homogenizing emulsion pump/pipeline high shear dispersing emulsifier is an efficient mixing and refining equipment that integrates mixing, dispersion, crushing, dissolution, refinement, depolymerization, homogenization, and emulsification. The main working components are composed of stator and rotor. The rapid operation of the rotor generates centrifugal and hydraulic forces, while the stator remains stationary. Through the precise combination of rotor and stator, strong shear force is generated during high-speed rotation, which exerts a comprehensive effect on the material, including strong shear, centrifugal extrusion, impact rupture, liquid layer friction, and uniform turbulence. Thus, immiscible solid, liquid, gas, and other media can be uniformly, finely dispersed, and emulsified in an instant. After repeated cycles, stable high-quality products are finally obtained.

|

Technical Specifications: |

| model | Motor power (kw) | Motor speed (r/min) | Processing capacity (L) | Import | Export |

| SRH-1-60 | 1.1 | 2900 | 0-1 | DN40 | DN32 |

| SRH-1-80 | 1.5 | 0-1.5 | DN40 | DN32 | |

| SRH-1-100 | 2.2 | 0-3 | DN40 | DN32 | |

| SRH-1-130 | 4 | 0-4 | DN40 | DN32 | |

| SRH-1-140 | 5.5 | 0-5 | DN50 | DN40 | |

| SRH-1-165 | 7.5 | 0-8 | DN50 | DN40 | |

| SRH-1-180 | 11 | 0-12 | DN65 | DN50 | |

| SRH-1-190 | 15 | 0-20 | DN65 | DN50 | |

| SRH-1-200 | 22 | 0-25 | DN65 | DN50 | |

| SRH-1-210 | 30 | 0-35 | DN80 | DN65 | |

| SRH-1-230 | 45 | 0-50 | DN100 | DN80 | |

| SRH-1-245 | 55 | 0-75 | DN100 | DN80 | |

| SRH-1-260 | 75 | 0-90 | DN125 | DN100 | |

| SRH-1-275 | 90 | 0-110 | DN125 | DN100 | |

| SRH-1-280 | 132 | 0-130 | DN125 | DN100 |

|

*The above table is for reference only and can be customized according to customer requirements.

*This equipment can be customized according to customer materials to meet process requirements, such as high viscosity, enhanced homogenization function, and heat sensitive materials. |

Product Structure: |

Homogenizing emulsion pump/pipeline high shear dispersing emulsifier is an efficient mixing and refining equipment that integrates mixing, dispersion, crushing, dissolution, refinement, depolymerization, homogenization, and emulsification. The main working components are composed of stator and rotor. The rapid operation of the rotor generates centrifugal and hydraulic forces, while the stator remains stationary. Through the precise combination of rotor and stator, strong shear force is generated during high-speed rotation, which exerts a comprehensive effect on the material, including strong shear, centrifugal extrusion, impact rupture, liquid layer friction, and uniform turbulence. Thus, immiscible solid, liquid, gas, and other media can be uniformly, finely dispersed, and emulsified in an instant. After repeated cycles, stable high-quality products are finally obtained. |

|

|

|

Working Principle: |

Homogenizing emulsion pump/pipeline high shear dispersing emulsifier is an efficient, fast, and uniform method for distributing one or more phases into another continuous phase, and in general, the phases are immiscible with each other. Due to the high tangential velocity generated by the high-speed rotation of the rotor and the strong kinetic energy brought by high-frequency mechanical effects, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tearing, and turbulence in the narrow gap between the stator and rotor. As a result, the immiscible solid, liquid, and gas phases are instantly uniformly and finely dispersed and emulsified under the joint action of corresponding mature processes and appropriate additives. After high-frequency cycling, stable high-quality products are finally obtained. |

|

Product details: |

|

| Pipeline type homogeneous emulsion pump (three-stage) |

|

Technical Specifications: |

| model | Motor power (kw) | Motor speed (r/min) | Processing capacity (L) | Import | Export |

| SRH-3-60 | 4 | 2900 | 0-4 | DN40 | DN40 |

| SRH-3-100 | 7.5 | 0-8 | DN50 | DN40 | |

| SRH-3-120 | 11 | 0-12 | DN50 | DN40 | |

| SRH-3-140 | 15 | 0-18 | DN50 | DN50 | |

| SRH-3-165 | 22 | 0-22 | DN65 | DN50 | |

| SRH-1-200 | 37 | 0-30 | DN80 | DN50 | |

| SRH-1-220 | 55 | 0-40 | DN100 | DN65 | |

| SRH-1-240 | 75 | 0-55 | DN100 | DN65 | |

| SRH-1-260 | 90 | 1440 | 0-65 | DN125 | DN80 |

| SRH-1-300 | 110 | 0-80 | DN125 | DN100 | |

| SRH-1-360 | 132 | 0-100 | DN150 | DN125 | |

| SRH-1-380 | 160 | 0-120 | DN150 | DN125 | |

| SRH-1-400 | 185 | 0-140 | DN150 | DN125 |

|

*The above table is for reference only and can be customized according to customer requirements.

*This equipment can be customized according to customer materials to meet process requirements, such as high viscosity, enhanced homogenization function, and heat sensitive materials. |

Product Structure: |

Homogenizing emulsion pump/pipeline high shear dispersing emulsifier is an efficient mixing and refining equipment that integrates mixing, dispersion, crushing, dissolution, refinement, depolymerization, homogenization, and emulsification. The main working components are composed of stator and rotor. The rapid operation of the rotor generates centrifugal and hydraulic forces, while the stator remains stationary. Through the precise combination of rotor and stator, strong shear force is generated during high-speed rotation, which exerts a comprehensive effect on the material, including strong shear, centrifugal extrusion, impact rupture, liquid layer friction, and uniform turbulence. Thus, immiscible solid, liquid, gas, and other media can be uniformly, finely dispersed, and emulsified in an instant. After repeated cycles, stable high-quality products are finally obtained. |

|

Working Principle: |

Homogenizing emulsion pump/pipeline high shear dispersing emulsifier is an efficient, fast, and uniform method for distributing one or more phases into another continuous phase, and in general, the phases are immiscible with each other. Due to the high tangential velocity generated by the high-speed rotation of the rotor and the strong kinetic energy brought by high-frequency mechanical effects, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tearing, and turbulence in the narrow gap between the stator and rotor. As a result, the immiscible solid, liquid, and gas phases are instantly uniformly and finely dispersed and emulsified under the joint action of corresponding mature processes and appropriate additives. After high-frequency cycling, stable high-quality products are finally obtained. |

|

Product details: |

|

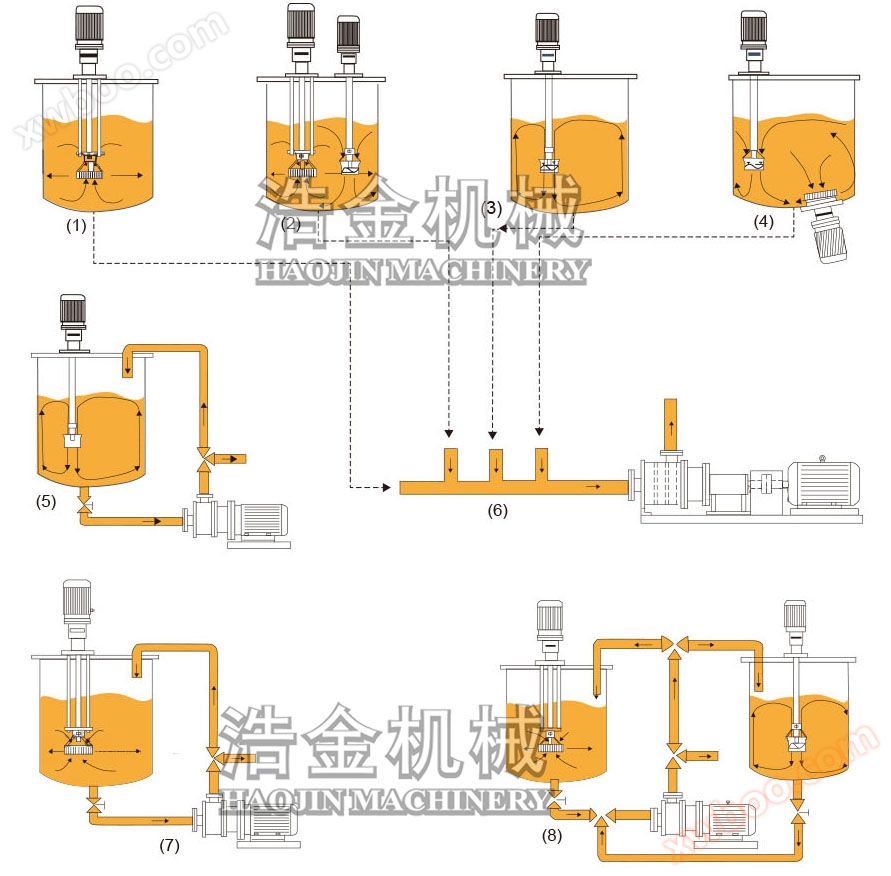

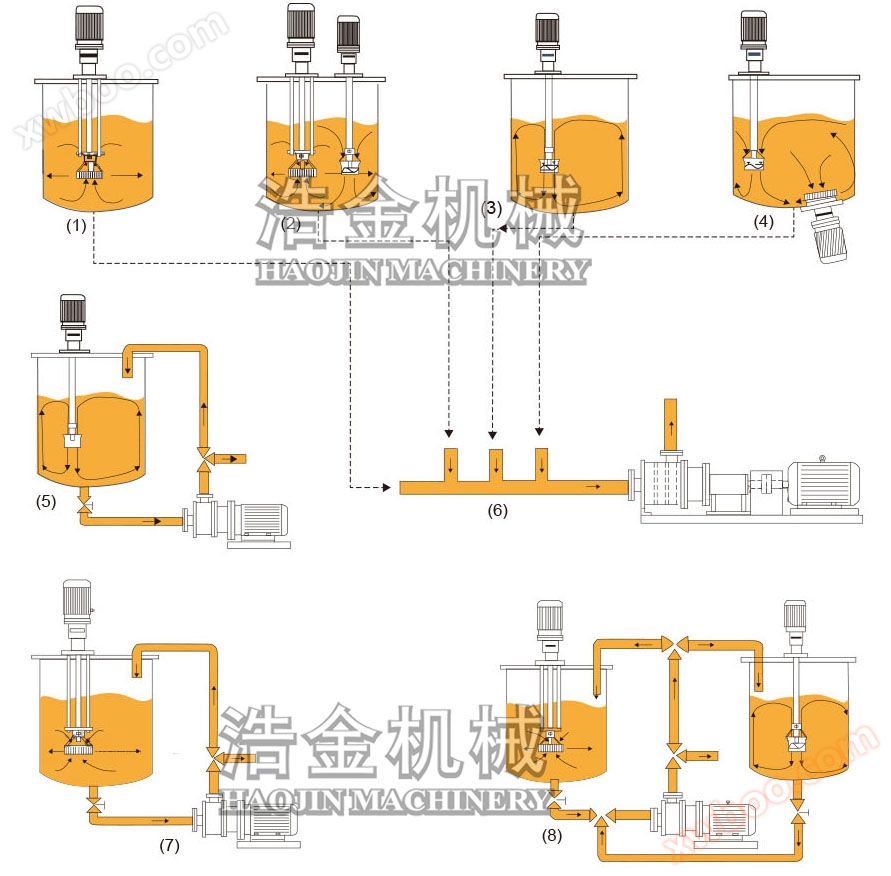

Product combination: |

|

Notes: |

The pipeline emulsion pump adopts a specially designed combination of high-speed rotor and stator. Under the drive of the motor, the rotor generates strong kinetic energy with extremely high linear velocity and high-frequency mechanical effects, causing the material to be subjected to a combination of shear, centrifugal compression, liquid layer friction, impact tearing, and turbulence in the precise gap between the rotor and stator, thereby achieving the effects of dispersion, grinding, and emulsification. Configure multi-stage rotors, stator combinations, and composite structures according to different process requirements. The characteristics of this machine are large processing capacity, online continuous production, narrow particle size distribution range, high uniformity, energy saving and high efficiency, low noise, smooth operation, no dead corners, and efficient material dispersion and shearing. Mechanical seals are vulnerable components, and their lifespan is related to working conditions and maintenance. The mechanical seal on this machine relies on materials for cooling, so it is strictly prohibited to operate without materials in the chamber of the mechanical seal to avoid damaging the mechanical seal. When encountering solidified materials, it is necessary to clean the materials in the working chamber with solvents before the end of each shift. Check whether the seals at the inlet and outlet of the emulsion pump are intact, and whether there are any impurities, metal debris, or other substances that may damage the equipment mixed into the machine body. Check whether the entire machine, especially the electric motor, is damaged during transportation or delivery, and install safety contact electrical devices when connecting the power switch. Before connecting the inlet and outlet of this device to the process pipeline, the process pipeline must be cleaned. Only after ensuring that the process pipeline is free of welding slag, metal shavings, glass shavings, quartz sand and other substances that may damage the equipment, can it be connected to this machine. The installation position should be kept perpendicular and horizontal to the container. When tilting, it is necessary to ensure good sealing, moisture resistance, dust prevention, moisture prevention, and explosion prevention. Before starting up, connect the cooling water of the mechanical seal first. When stopping, turn off the power first and then cut off the cooling water. The cooling water can be tap water, and the cooling water pressure should be ≤ 0.2Mpa. The material must enter the working chamber before starting up, and it must be ensured that it does not operate in a state of material breakage to avoid mechanical seals being burned out or affecting their service life due to high temperature caused by idling. Ensure that the direction of the motor is consistent with the direction mark of the spindle before starting the machine. Reverse rotation is strictly prohibited. When using the machine, liquid materials must be continuously inputted or maintained in a certain amount in the container. Empty operation should be avoided to prevent materials from generating high temperatures or crystallization solidification in the working chamber, which may damage the equipment. It is strictly prohibited to idle. Pipeline emulsion pumps are used for emulsification, homogenization, and dispersion of products in industrial production. This machine is composed of three or more layers of dual interlocking rotors. After the material is sucked into the rotor, it undergoes hundreds of thousands of shearing actions. Through layer by layer shearing, dispersion, and emulsification, it achieves the effect of highly dispersing multiphase liquids and rapidly refining fixed particles. |